How Thick Can a 6000 Watt Laser Cut

Select your file at the laser, put your engraving material in the machine, shut the door, and press GO. The laser will do the rest!

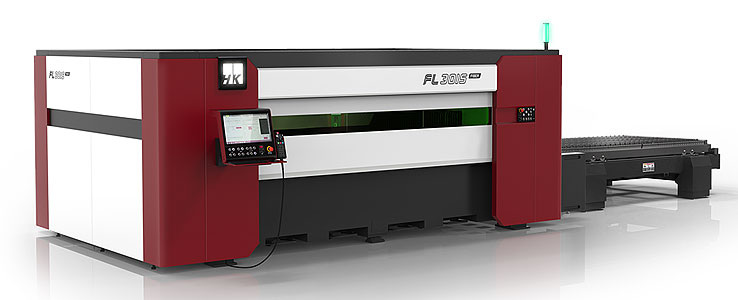

GSS Machinery lasers are easy to use.

STJ6040 desktop laser engraver (desktop laser cutter) with CO2 laser tube is a hobby laser with tabletop and benchtop design for small business or home business, which is used to etch, engrave and cut signs, logos, letters, numbers, patterns on wood, plywood, MDF, cardboard, leather, fabric, plastic, acrylic, rubber, glass, paper. Now the 2022 best budget mini desktop laser cutting and engraving machine for sale at cost price.

The refractive mirrored is the core of the beam delivery apparatus. It is responsible for directing the beam the right way. The lens is protected from contamination by a protective covering and clean positive pressure protective gases.

Add the ability to engrave and mark metals with the addition of a fiber laser to your CO2 laser machine, available in the Fusion Pro Series. A dual source laser machine will expand your capabilities even further, and help increase your business's product offerings and profits.

A 5-axis automatic laser cutting robot costs between $49,000 and $83,500. It is flexible for 3D dynamic metal cutting of multi-angle and multidimensional materials in industrial manufacturing.

Select your file at the laser, put your engraving material in the machine, shut the door, and press GO. The laser will do the rest!

GSS Machinery lasers are easy to use.

It's easy as 1-2-3. You can use our laser machines as standard printers to keep your workflow simple.

If you're looking to start your business with an used or new laser cutter to make money, you may wonder how does it cost? and what is the average cost in your area? The best budget laser cutter costs from about $2,600 to $300,000, excluding the price of shipping, tax rates, customs clearance, service, and technical support. Costs depend on the brand and type, and whether you want any extra features, including personalized design, custom table size, laser generator and power, rotary attachment, controller, software, parts, accessories, upgrades, setup, debugging, and other special features. Here are the average costs list.

Need to buy more equipment for your agency or home studio? Then also check out the best office chairs in general, and the best office chairs for back pain, as well as the best desks, the best printers and the best 3D printers.

According to the material and thickness of the raw material to be cut, adjust the system cutting parameters of the equipment correspondingly;

The beam emitted by the laser generator is focused by the optical path system into a laser beam of high power density. The beam is irradiated onto the surface of the part to bring the part to a melting point or boiling point, while the high-pressure gas coaxial with the beam blows away the molten or vaporized material. As the beam moves relative to the part, the material is slit finally, thereby achieving the purpose of cutting.

Laser cutting machines can be classified as fiber laser machines or CO2 laser machines depending on their laser sources.

GSS Machinery metal and ceramic Laser Tubes combine the benefits of longer lifespan and lower recharge costs while providing higher-quality cutting, engraving and engraving.

Next, push the main switch to activate the main power. Turn the key switch in the control panel. This is machine-specific, and does not apply to all lasers. The system will begin to quote once all covers are closed with safety circuit breakers. After turning the machine on, the table will move all of the way down and the pro laser head will move to the zero position (located near the upper left corner). If the LED light flashes slowly but steadily and makes a noise, then the machine has successfully completed the reference process.

Thickness: A 40W to 45W CO2 laser, such as the Muse Core or 3D autofocus, can generally cut up to 14" thick wood, whereas a 90W tube laser, such as the P-Series PS24 or Muse Titan, can cut up to 12" thick wood.

High-wattage laser cutting machines, on the other hand, are typically much more expensive than entry-level models. Some laser cutter models range in price from $4,000 to $15,000.

Laser power of 80W. A laser can typically cut up to 10mm acrylic and up to 9mm soft woods.